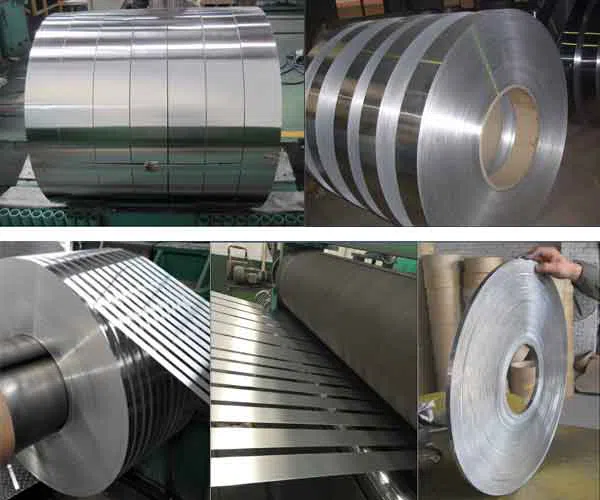

As a professional factory of Heat Transfer Aluminum Strip materials, our bare or claded aluminum strip is widely used in automotive radiator, charge air cooler, oil cooler, power station air cooler, condenser and evaporator, microchannel heat exchanger. Brazing Heat Transfer Aluminum Strip is with tight tolerance according to EN and ASTM standard. Special thickness and alloys are available as per your request.

As a professional factory of Heat Transfer Aluminum Strip materials, our bare or claded aluminum strip is widely used in automotive radiator, charge air cooler, oil cooler, power station air cooler, condenser and evaporator, microchannel heat exchanger. Brazing Heat Transfer Aluminum Strip is with tight tolerance according to EN and ASTM standard. Special thickness and alloys are available as per your request.

Strips | Sheets | |

Thickness | 0.051mm--3.0mm | 0.4mm--6.35mm |

Width | 5mm--1600mm | 500--1600mm |

Length | Max. 10000mm | |

Edge Quality | Trimmed | Trimmed And Slit; Sawn |

Inside Diameter | 305mm, 405mm, 505mm Paper Core, Aluminium Core, Without Core. | |

Outside Diameter | Max. 1600mm Without Connect Point |

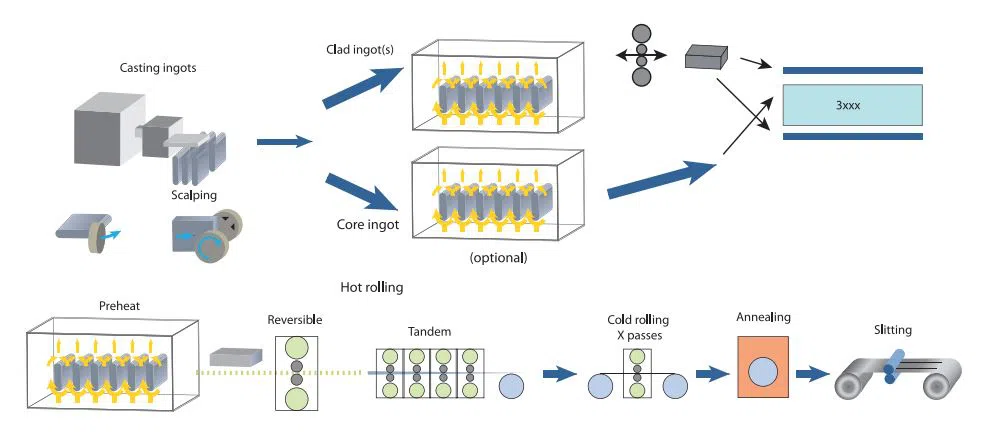

Cladding

Cladding | One Side; Both Sides |

Cladding Rate | 5%, 7.5%, 10%, 13%, 15% (Other Clad Percentages Available Upon Request) |

Cladding Tolerance | Cladding Thickness Of 1.5%--<4%: +> |

Surface

Quality | Mill Finish; For Thickness 0.3--3.5mm, Chemically Degreased |

Marking | Ink Marking |

Physical Property Data of Heat Transfer Aluminum Strip

Alloy | Temper | Thickness | Tolerance | Clad | Tensile | Yield | Elongation | Application |

3003 | H14 | 0.08~0.12 | ±0.005 | None | 150~200 | ≥120 | 1 | Evaporator Fin And Plate |

3003 | H26 | 0.3~0.35 | ±0.015 | None | 190~220 | ≥160 | 8 | Glass Mounting Bracket Material |

3003 | H14 | 0.06~0.1 | ±0.005 | None | 150~200 | ≥120 | 1 | Radiator Fin And Plate |

4343/3003/4343 | H14 | 0.06~0.1 | ±0.005 | 8~12 | 150~200 | ≥120 | 1 | |

4343/3003/4343 | H14 | 0.08~0.12 | ±0.005 | 8~12 | 150~200 | ≥120 | 1 | Parallel Condenser Fin |

4343/3003/4343 | H14 | 0.1~0.12 | ±0.005 | 8~12 | 150~120 | ≥120 | 1 | Charge Air Cooler Material |

4045/3003/4045 | H14 | 0.1~0.12 | ±0.005 | 8~12 | 150~200 | ≥120 | 1 | |

1060 | O | 0.35~0.4 | ±0.02 | None | 55~95 | ≥15 | 25 | Air Cooling Fin Material For Tubes |

1100 | O | 0.35~0.4 | ±0.02 | None | 75~105 | ≥25 | 25 | |

3003 | O | 0.2~0.3 | ±0.01 | None | 100~150 | ≥45 | 15 | Aluminium For Heating Element |

3003 | H16 | 0.5~0.7 | ±0.02 | None | 150~210 | ≥120 | 1 | |

4047 | H18 | 0.05~0.1 | ±0.005 | None | ≥200 | ≥170 | 0.5 | |

4047 | O | 0.4~0.5 | ±0.02 | None | 80~140 | ≥35 | 12 | Welding Wire |

7072 | H19 | 0.12~0.15 | ±0.005 | None | 145~172 | ≥15 | 0.5 | Fin Stock |

4A13 | H18 | 0.05~0.1 | ±0.005 | None | ≥190 | ≥16 | 0.5 | Aluminium For Heating Element |

4104 | H18 | 0.05~0.1 | ±0.005 | None | ≥220 | ≥190 | 0.5 | |

3003 (Inner Fin) | O | 0.2~0.3 | ±0.007 | None | 100~150 | ≥45 | 15 | Oil Cooler |

6951(Inner Fin) | O | 0.2~0.3 | ±0.007 | None | 115~165 | ≥50 | 15 | |

3003(External Fin) | H14 | 0.1~0.15 | ±0.005 | None | 150~200 | ≥120 | 1 | |

3003(Inner Fin) | O | 0.2~0.3 | ±0.007 | None | 100~150 | ≥45 | 15 | Engineering Machinery |

3003(Inner Fin) | H12 | 0.2~0.3 | ±0.007 | None | 120~160 | ≥85 | 2 | |

3003(External Fin) | H14 | 0.1~0.15 | ±0.005 | None | 150~200 | ≥120 | 1 |

Physical Property Data of Plate of Heat Transfer Aluminum Strip

4343/3003 | O | 1.2~3.0 | ±0.03 | 5~10 | 100~150 | ≥45 | 25 | Radiator Fin And Plate |

4343/3003/7072 | O | 1.2~3.0 | ±0.03 | 5~10 | 100~150 | ≥45 | 25 | |

4343/3003/4343 | O | 0.4~0.5 | ±0.02 | 8~12 | 100~150 | ≥45 | 27 | Evaporator Fin And Plate |

4045/3003/4045 | O | 0.8~1.2 | ±0.03 | 8~12 | 100~150 | ≥45 | 27 | |

4045/3003/4045 | O | 2~3 | ±0.05 | 8~12 | 100~150 | ≥45 | 25 | Charge Air Cooler Material |

4045/3003/4045 | O | 0.5~0.8 | ±0.02 | 15~20 | 100~150 | ≥45 | 25 | Oil Cooler |

4104/3003/4104 | O | 0.5~0.8 | ±0.02 | 15~20 | 100~150 | ≥45 | 25 | |

4104/3003/4104 | H14 | 0.6~0.8, | ±0.02 | 13~17 | 150~200 | ≥120 | 3 | Engineering |

4004/3003/4004 | H14 | 0.6~0.8, | ±0.02 | 13~17 | 150~200 | ≥120 | 3 |

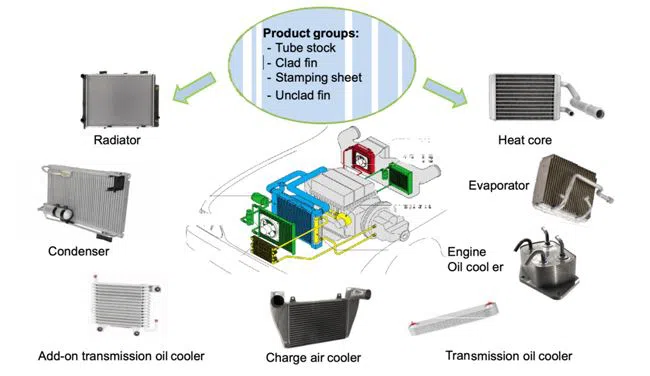

Applications:

1. Unclad fin stock for radiators, charge air coolers, heaters, and more

2. Clad strips for welded or folded tubes for radiators

3. Clad header plates and side plates for various types of heat exchangers

4. Clad fin stock for condensers

5. Clad plates for evaporators and oil coolers.

FAQ:

Q:What the main products you can supply?

A:We are the professional and famous factory in China for aluminum circle, aluminum sheet, aluminum foil, Heat Transfer Aluminum Strip, color coated aluminum coil etc.

Q:How about the samples? Is it free to extra fees?

A:Yes,we would like to suply the free samples before order,but the freight cost should pay by you.

Q:What is your payment terms?

A:Commonly two payment term for new customers.

1 ) 30%T/T as deposit,70% balance against B/L copy.

2)100% Irrevocable L/C at sight.

Q:How about the samples? Is it free to extra fees?

A:Yes,we would like to suply the free samples before order,but the freight cost should pay by you.

Q:How long is your delivery time?

A: After the deposit , all the finished goods will delivery within 15-25 days.

Q:How to control and guarantee your shipment quality ?

1. Every patch goods should check three times by quality control department before delivery.

2. ISO,SGS the third party quality control department can check before delivery.

رمز ريال قطري